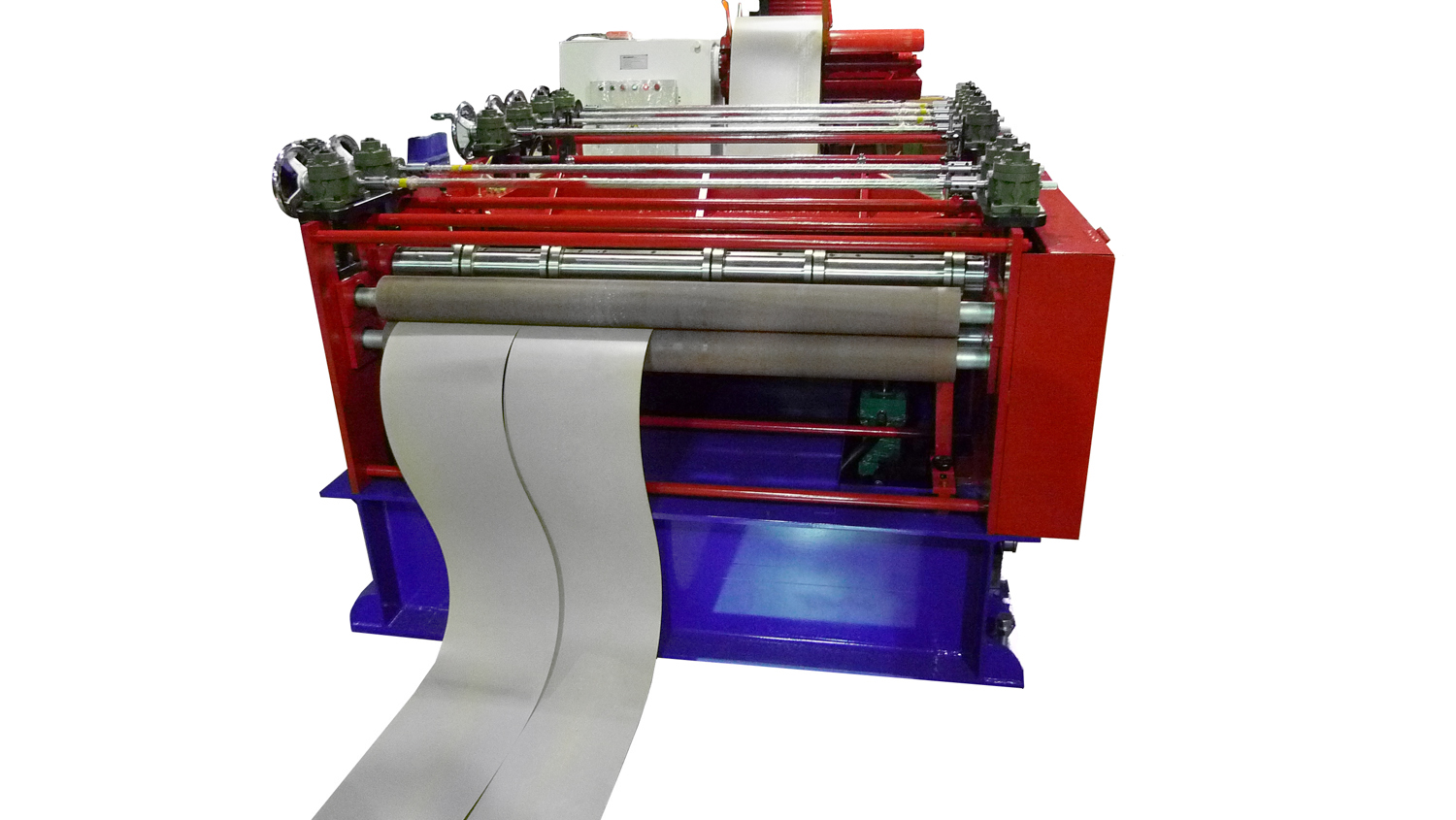

We have developed this compact fully automatic slitting line mainly for the door industry. Due to the variety in styles, width, and thickness of the door panels, having such a production line on-site is an economical complement to door manufacturing, or even metal suppliers for flexible jobs of medium volumes.

The system has variable speed via various optical sensors, thus having no need for loop or pit. It is capable of processing multiple bundles of coils with separating disks. The larger coil goes thru several pairs of flattening roller before slitting. The rotary slitting tool is removable with dual slitting surface to reduce downtime and ease of service. The recoiling mandrel is powered with tensioning mechanism for a tight winding. The unloading is easy with a motorized hydraulic coil car.