Most of the main parts of a rolling shutter door can be manufactured with a rollforming system. This includes slat, bottom rail, guide channel, and housing cover. We have adapted many features of our rollforming system to bring the manufacturing of such parts as efficient and productive as possible, by adding various peripheral modules in-line. We are also capable of employing different types of rollforming mills to satisfy each demands from standard, side-by-side, dual-level, to rafted.

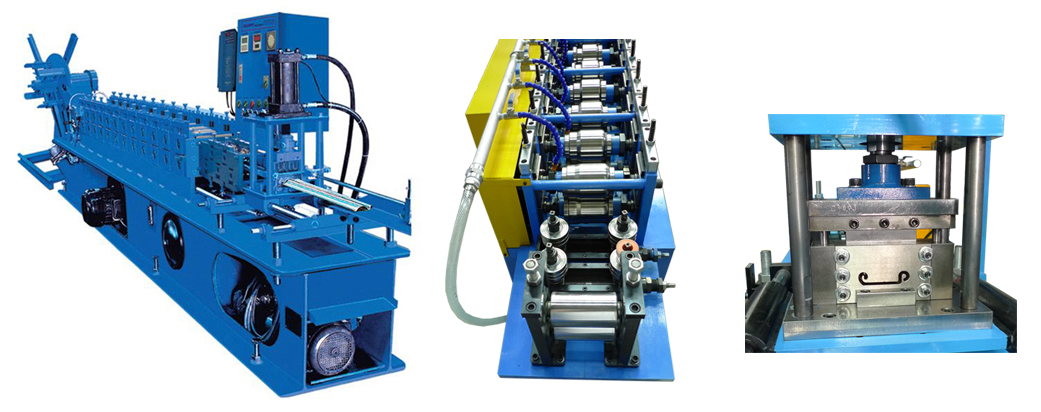

We have standardized many features in the fully automatic manufacturing line of rolling shutter door slat. We start by having an intuitive user interface on a colored touchscreen, for ease of operator input with minimum calculation and human error. There are various features such as insufficient material check and buzzer with LED tower light to allow just one single operator to manage multiple machines. There are also multiple production modes and memory settings available to setup multiple jobs of either single slat to hundreds of doors of different width and height.

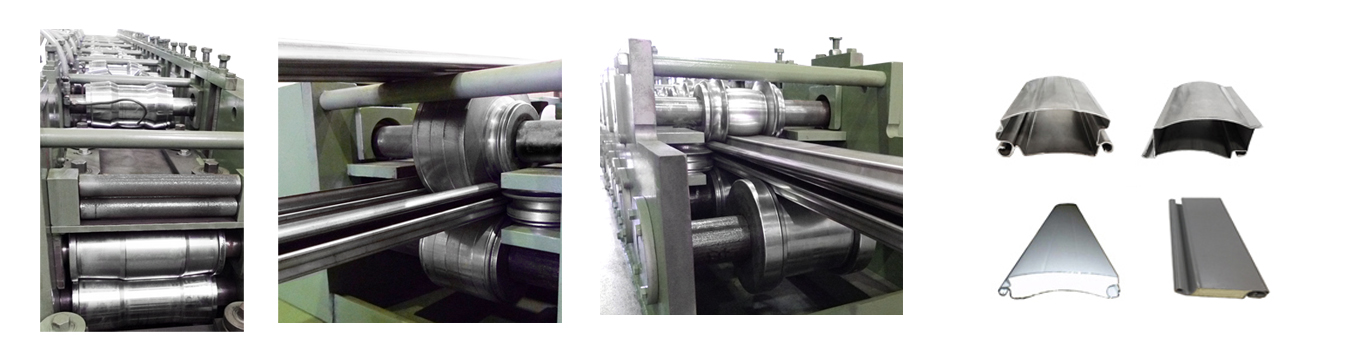

Due to the growing demands of energy efficiency rating and safety standards in the door industry, we have upgraded our traditional rollforming machines for manufacturing products to accommodate such conditions. Utilizing a dual level rollforming system to roll form the top and bottom skin separately in the first stage. As the two layers come together, a pre-heating furnace raise the surface temperature to appropriate level for the foam injection system. Once injected, the two layers combine to enter the second stage to be roll formed at the edges. This creates a good seal and applies enough pressure for the foam to expand.

By changing the chemical mixture of the foam, different desired characteristics of the door can be achieved. For energy efficient insulation and thermal barrier requirements, foam injection of PUR/PIR would be the most ideal. For a fire-rated door, mineral wool such as rock wool insertion in-between the double skin slat offers the most protection, and we are capable of providing the appropriate feeding mechanism of such material.

We have implemented various innovative features to maximize the productivity of manufacturing rolling shutter door components.

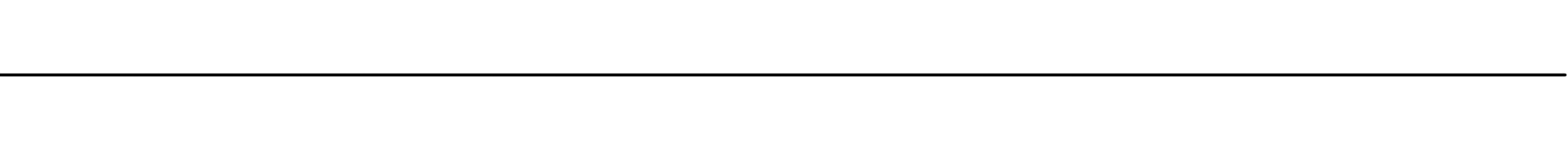

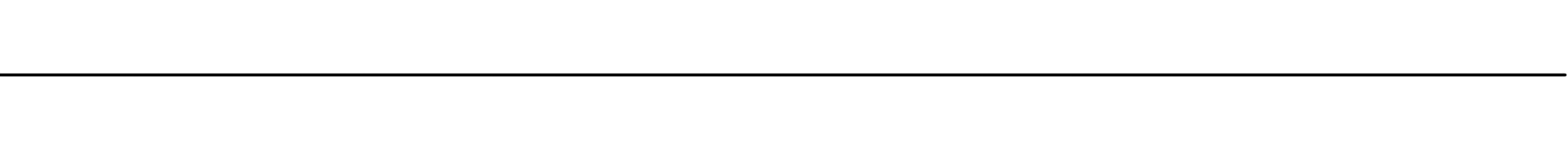

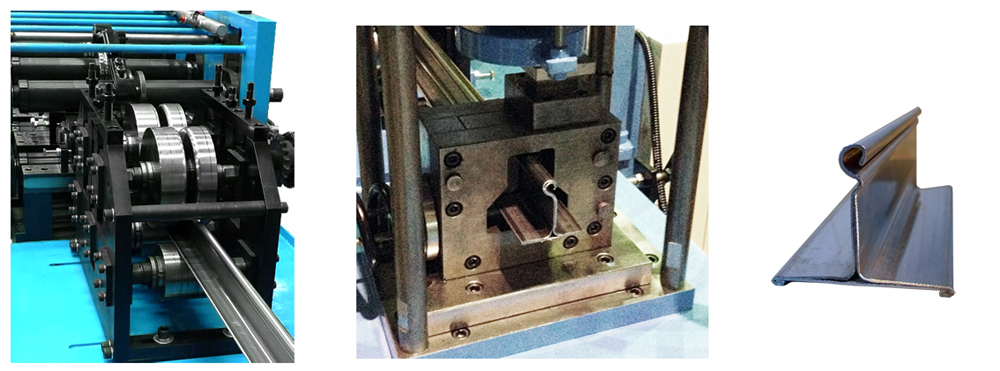

We are capable of producing two popular profiles in one rollforming system. They are both double skin for extra structural support. One is a reverse "T" shape and the other is "L" shape. All necessary perforation and notching are produced in-line.

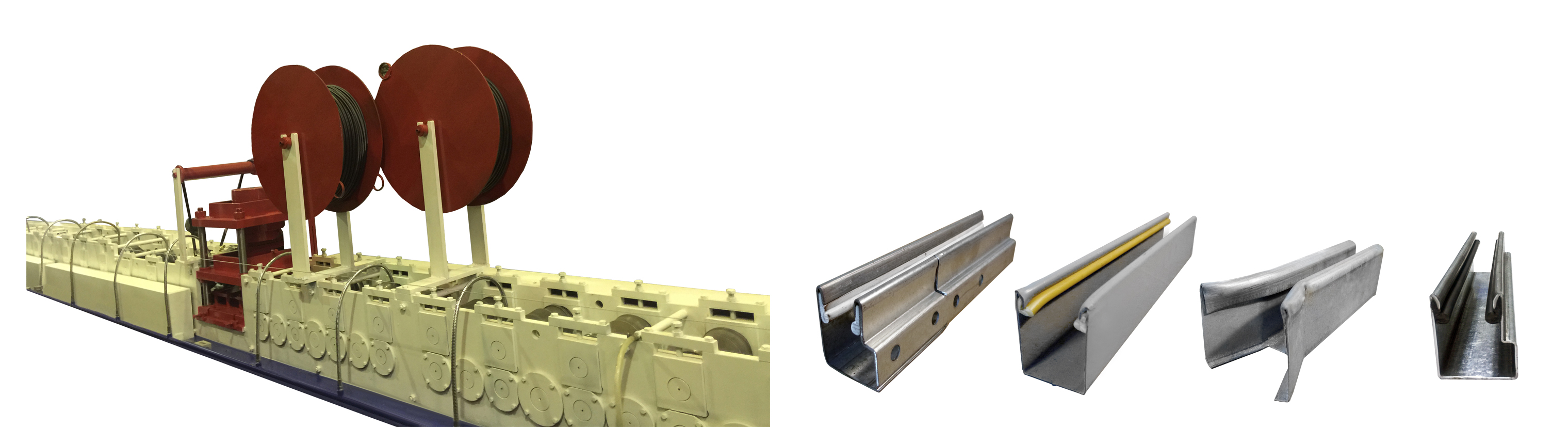

We are capable of producing one pair of handed guide channel in a single rollforming system. All necessary perforation and notching are produced in-line. The addition of PVC/plastic inserts for quiet operation can be incorporated in the system as well.